|

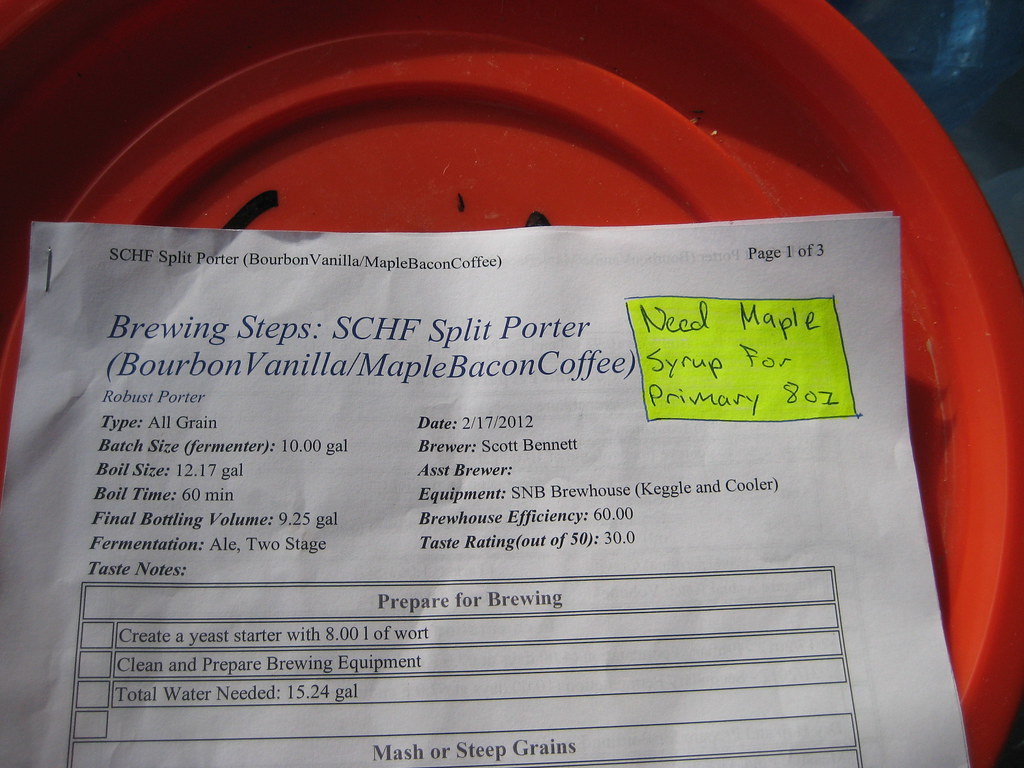

| The brewsheet |

In anticipation of this year's Southern California Homebrew Festival, taking place at Lake Casitas the first weekend in May, I set aside a Sunday to push my system to produce 10 gallons of beer with the plan on donating half to AHP Brewclub and the other to Brewcommune. When it came time to decide what to brew I had several ideas, would it be an IPL, a mild or bitter to be severed on cask or something completely new?

Last year took up 2 beers; an English-Belgian-American Double IPA that I called Scottland's Yard and a porter with 5 different kinds of peppers called Campsite Smoked Jalapeño Porter. Both beers were a hit and I got a lot of good feedback particularly on the Campsite Smoked Jalapeño Porter. It also happened to be the first keg to kick which I took as a good sign. I realized that I actually hadn't brewed a porter since then so I figured why not brew up a double batch of porter for this year as well

|

| Assistant Brewer in training |

If I was going to do it again I wanted to develop a base porter that I could use to create 2 different beers in secondary. To one half I plan on adding 4 vanilla beans in secondary and straight bourbon when I keg it, I am calling that batch BaseCamp Dessert and the other will become a porter with maple syrup, bacon and coffee called BaseCamp Breakfast. For BaseCamp Breakfast I have already added the first of 2 maple syrup additions by adding 18oz of maple syrup that I pasteurized while the main batch was cooling. The second addition will be used to prime keg. I will talk about what I will be doing to each batch more once I move them to secondary.

When it came time to brew the beer I started by making a starter of WLP007 that I could use one vial for all 10 gallons of beer. My plan really was to make the primary of both beers pretty identical and really create two different beers in secondary so using the same yeast was a no-brainer. I'm also hoping to be able to use the yeast from the Dessert portion to get a house culture of WLP007 going for this years Imperial Rhino Stout whose brewday is right around the corner. At around 7% the Dessert version is right at the upper limit for reusing yeast.

|

| Overflowing with mash |

Brewing 10 gallons of the beer required the most amount of grain yet, even with the addition of 3 lbs of light DME I used so much grain that when I put the top on the mash tun the volume it displaced poured over the side. Still after 60 minutes I held a steady 154 temp, which was about 2 degrees under my target, and got full starch conversion.

There was no way my stainless spoon was going to be able to handle the job so I few days before I brewed I used an Amazon gift card my brother gave me for my birthday to buy a 48" stainless paddle. I had planned on buying a $10 wood paddle buy they had none in stock. I love my new paddle, though I had to close the garage while stirring as I kept hitting it.

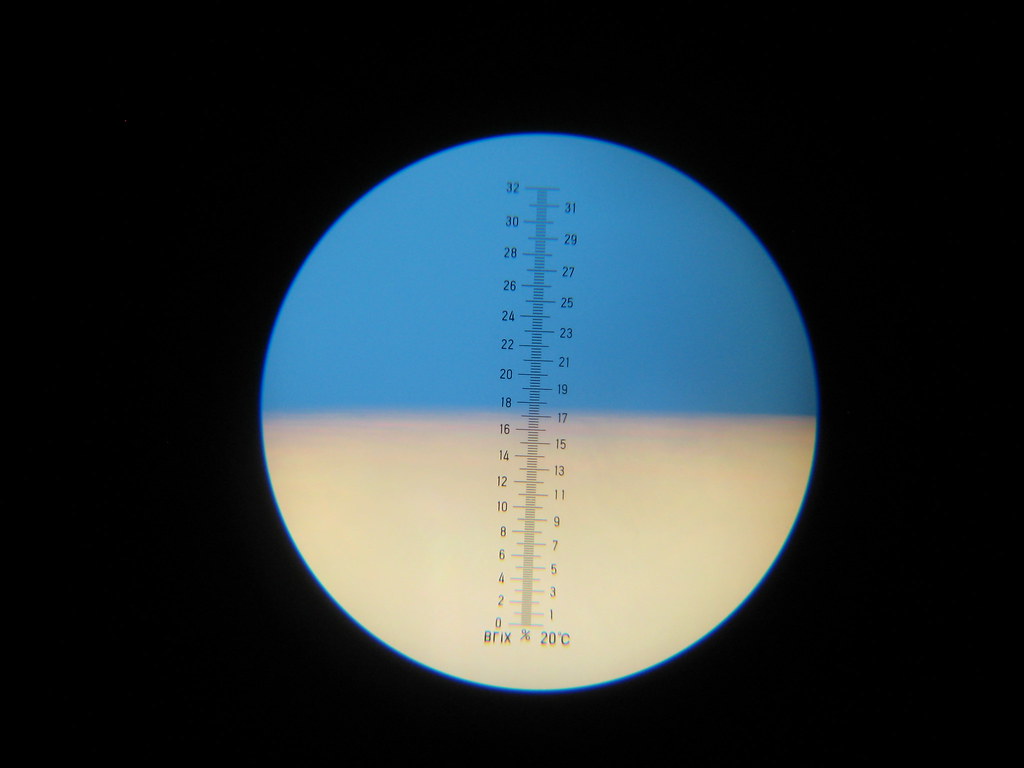

You might recall my frustration with the efficiency I'd been getting and more so to the point that even as I'd been lowering my efficiency I was still missing my target OG. I mentioned last time I brewed back in January that I had an idea where my problem was, my equipment settings. Between then and now I spent some time looking at what variables others with similar equipment were using. It turns out the default evaporation setting for a keggle (boil kettle made out of an old keg) was way off. If I recall correctly it was set at almost 20% and when I looked online most people where getting 10%. Adjusting this setting made all the difference in the world and I ended up with a 10 pt efficiency gain, pushing me into the 70s. I also got to test out the refractometer that Shawn gave me when I bought his old grain mill. The flap is broken off but it still works great you just have to hold it in place. I calibrated it against my hydrometer and ended the value in to the calibrate refractometer section of the brewing app I use.

Cheers

-SNB

Updates

BaseCamp Breakfast aka Maple-Bacon-Coffee

BaseCamp Dessert aka Bourbon-Vanilla

SCHF Split Porter (BourbonVanilla/MapleBaconCoffee)

Robust Porter

Type: All Grain

Date: 2/18/2012

Batch Size (fermenter): 10.00 gal

Brewer: Scott Bennett

Boil Size: 12.17 gal

Boil Time: 60 min

Equipment: SNB Brewhouse (Keggle and Cooler)

End of Boil Volume 10.92 gal

Brewhouse Efficiency: 71.00 %

Beer Profile

Est Original Gravity: 1.072 SG

Measured Original Gravity: 1.072 SG

Est Final Gravity: 1.019 SG

Estimated Alcohol by Vol: 7.0 %

Bitterness: 37.3 IBUs

Est Color: 34.8 SRM

Ingredients

Grain

13 lbs Pale Malt (2 Row) US (2.0 SRM)

3 lbs Munich Malt (9.0 SRM)

2 lbs 8.0 oz Barley, Flaked (1.7 SRM)

2 lbs Brown Malt (65.0 SRM)

1 lbs 8.0 oz Chocolate Malt (450.0 SRM)

1 lbs Caramel/Crystal Malt -120L (120.0 SRM)

8.0 oz Caramel/Crystal Malt - 60L (60.0 SRM)

3 lbs Light Dry Extract (8.0 SRM)

Hops

1.80 oz Magnum [11.09 %] - Boil 60.0 min

1.00 oz Northern Brewer [8.50 %] - Boil 10.0 min

Other

2.00 Items Whirlfloc Tablet (Boil 15.0 mins)

2.00 tsp Yeast Nutrient (Boil 15.0 mins)

Yeast

1.0 Starter 2000ml Dry English Ale (White Labs #WLP007)

Mash Profile

Mash Name: Single Infusion, Full Body, Batch Sparge Total Grain Weight: 26 lbs 8.0 oz Sparge Water: 7.64 gal

Mash Steps Mash In Add 30.40 qt of water at 167.8 F 156.0 F 60 min

Sparge Step: Drain mash tun, Batch sparge with 2 steps (3.82gal, 3.82gal) of 168.0 F water

Updates

BaseCamp Breakfast aka Maple-Bacon-Coffee

BaseCamp Dessert aka Bourbon-Vanilla

SCHF Split Porter (BourbonVanilla/MapleBaconCoffee)

Robust Porter

Type: All Grain

Date: 2/18/2012

Batch Size (fermenter): 10.00 gal

Brewer: Scott Bennett

Boil Size: 12.17 gal

Boil Time: 60 min

Equipment: SNB Brewhouse (Keggle and Cooler)

End of Boil Volume 10.92 gal

Brewhouse Efficiency: 71.00 %

Beer Profile

Est Original Gravity: 1.072 SG

Measured Original Gravity: 1.072 SG

Est Final Gravity: 1.019 SG

Estimated Alcohol by Vol: 7.0 %

Bitterness: 37.3 IBUs

Est Color: 34.8 SRM

Ingredients

Grain

13 lbs Pale Malt (2 Row) US (2.0 SRM)

3 lbs Munich Malt (9.0 SRM)

2 lbs 8.0 oz Barley, Flaked (1.7 SRM)

2 lbs Brown Malt (65.0 SRM)

1 lbs 8.0 oz Chocolate Malt (450.0 SRM)

1 lbs Caramel/Crystal Malt -120L (120.0 SRM)

8.0 oz Caramel/Crystal Malt - 60L (60.0 SRM)

3 lbs Light Dry Extract (8.0 SRM)

Hops

1.80 oz Magnum [11.09 %] - Boil 60.0 min

1.00 oz Northern Brewer [8.50 %] - Boil 10.0 min

Other

2.00 Items Whirlfloc Tablet (Boil 15.0 mins)

2.00 tsp Yeast Nutrient (Boil 15.0 mins)

Yeast

1.0 Starter 2000ml Dry English Ale (White Labs #WLP007)

Mash Profile

Mash Name: Single Infusion, Full Body, Batch Sparge Total Grain Weight: 26 lbs 8.0 oz Sparge Water: 7.64 gal

Mash Steps Mash In Add 30.40 qt of water at 167.8 F 156.0 F 60 min

Sparge Step: Drain mash tun, Batch sparge with 2 steps (3.82gal, 3.82gal) of 168.0 F water

Pictures

|

| New paddle |

|

| Ingrediants |

|

| Boil Keggle |

|

| False bottom |

|

| Dip tube |

|

| Preheating the tun |

|

| The main setup |

|

| Stirring in the mash |

|

| Vorlofing the first sparge |

|

| First runnings batch sparge #1 |

|

| First wort hops |

|

| Stirring the second sparge |

|

| Batch sparge #2 |

|

| Batch sparge #3 |

|

| Biggest boil my keggle has ever seen |

|

| Cooling down |

|

| Pasteurizing the maple syrup |

|

| Adding maple syrup to primary |

|

| 5 even gallons in both |

|

| The left over |

|

| Chilling |

|

| The new to me Refractometer |

|

| The Brix reading on the Refractometer |

|

| Brewzer Calculator: Refractometer Brix to Specific Gravity Prior to Calibration |

|

| Away in the cellar to ferment for a couple of weeks |

ReplyDeleteAFAB Enterprises is founded on the understanding that many manufacturing and processing facilities need accurate,

reliable and repeatable results from refractometer equipment - but they don't necessarily have to spend tens of thousands

to get those results. Through a series of common sense approaches to the design and engineering of our products,

AFAB offers its customers the best of both worlds; dependability and affordability. Yes, anyone can probably spend more

on refractometer equipment, but for most of the companies that use this equipment it is costly overkill.

Refractometer

Also more details click here